Rope Access Inspection Services

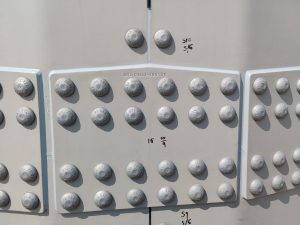

Bladestar Renewables Ltd. utilise rope access as one of our many inspection services. Due to the nature of being up close and personal with the blade/tower we are able to professionally assess damages/defects in great depth. This service is usually taken to coincide with our blade repair packages or to investigate a more serious defect found by drone. Along with the inspection we also offer testing of the Lightning Protection System which can be completed at the same time.

All inspection reports are generated using our specialised in-house reporting template which will be complete with all the information required to move forward with repairs if necessary.

Rope Access inspections consist of an internal, external and LPS check. This full inspection check list will generally take around 10 hours to complete ensuring a thorough inspection of all aspects of the blade.

It is crucial that internal blade inspections are completed to ensure the structural integrity of the web, webfoot and inner shell. In our experience majority of structural damages start via an internal damage that his been missed or not properly inspected by competent blade technicians. Poor quality internal factory repairs can also be a starting point for serious defects.

Drone Inspection Services

Bladestar Renewables Ltd. adopt the latest UAV( Unmanned Aerial Vehicle) drone technology, which maps a 360 degree virtual panoromic scan around the turbine tower and blades. This provides us with an in-depth report of your wind turbine system and aids our technicians in their assessment and completion of repairs and maintenance.

Drones play a critical role in Bladestar Renewables Ltd. professional and bespoke service, and our drone-technology assists us with periodic surveys of your system, reducing exposure time to working at height.

Contact us at Bladestar Renewables Ltd. to chat about how we can work together to keep your turbines turning.

what we do

What our clients say about us?

After suffering from Failures in Our hybrid cooling tower blades I was contacted by Blade Star who were confident they could provide a solution to enable us to

Repair our cracked blades and reuse them rather than disposing of them,

The repair procedure was fast, efficient, economical and it was well received as where the employees from blade Star

The repaired blades have been refitted to the cooling towers and have proved there worth and have been on the units for over a year with no failures,

Luke

West BurtonIn my role as supervisor, I oversee a major wind farm project in Germany. Due to design adjustments, some towers had to be sealed from the outside. We ordered a subcontractor to the site to carry out the work. The team leader was Chris Gillies from Bladestar Renewables Ltd. He had his team were very careful during the work process and extremely fast and cooperative. Punctuality was also a top priority. In addition, Bladestar were able to contribute very good suggestions for improving the sealing processes thanks to their many years of experience! The quality of the work carried out was very high. All in all, the team were a pleasure to work with. We would hire Bladestar again at any time!

Lars Alshut

EnerconWe were pleased with the blade work carried out. There were no additional charges compared to the quote estimate and the work was carried out in the estimated time period which was all encouraging. Also good flexibility in that our first dates needed to be postponed due to high winds. This was done without issue by bladestar.

Amy Carswell

The Greenspan AgencyBladestar showed an excellent technical knowledge and professionality executing works on site. The communication is also a strong point in all stages. They helped us to solve critical problems with a high quality ensuring our collaboration in future projects.

César Urdaniz Mendia

Vector RenewablesBladestar showed themselves with good communication before and during the project. The repair methodology was also transparently and openly communicated on a permanent basis so that all steps could be understood from a technical point of view. This helped us a lot in ensuring quality and we look forward to working with Bladestar again on future projects.