Blade Repair Specialists

Bladestar Renewables Ltd are multi-brand blade repair specialists with strong knowledge and experience on Siemens, LM, Enercon and Vestas blades.

Through our 20+ years of experience we have developed a unique and consistent repair methodology that bridges all blade manufacturers.

Rotor blades are one of the most expensive yet delicate components on a wind turbine system. It is critical that they are well inspected and maintained given the immense operational and environmental pressures they are subjected to.

A lightly eroded blade is almost guaranteed to affect the production of the turbine and can also through time propagate into a serious defect. The sooner any defects are repaired the better to increase the longevity of the blade and turbine.

Blade Repair Services

As a company with high expectations, we are changing the poor standards that have been set in this industry for too long. Our focus on being a safe and high quality organisation make us a stand out repair company from the competition.

For more technical insight into the blade repair activities we are engage in please read through our case studies below.

- Hole in the blade

- Core damage

- Cracks in Lamate

- Delamination

- Impact Erosion

- Laminate Erosion

- Laminate UV damage

- Bondline Cracks

- Gelcoat Damage

- Pin Holes

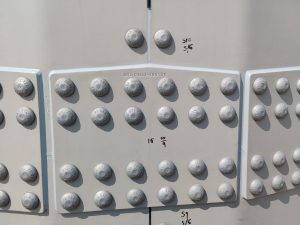

- LPS Damage

- Retrofit Damage

- Web reinforcements

- Web Cracks

- Failed Repair Rectification

- Quality Control

what we do

What our clients say about us?

After suffering from Failures in Our hybrid cooling tower blades I was contacted by Blade Star who were confident they could provide a solution to enable us to

Repair our cracked blades and reuse them rather than disposing of them,

The repair procedure was fast, efficient, economical and it was well received as where the employees from blade Star

The repaired blades have been refitted to the cooling towers and have proved there worth and have been on the units for over a year with no failures,

Luke

West BurtonIn my role as supervisor, I oversee a major wind farm project in Germany. Due to design adjustments, some towers had to be sealed from the outside. We ordered a subcontractor to the site to carry out the work. The team leader was Chris Gillies from Bladestar Renewables Ltd. He had his team were very careful during the work process and extremely fast and cooperative. Punctuality was also a top priority. In addition, Bladestar were able to contribute very good suggestions for improving the sealing processes thanks to their many years of experience! The quality of the work carried out was very high. All in all, the team were a pleasure to work with. We would hire Bladestar again at any time!

Lars Alshut

EnerconWe were pleased with the blade work carried out. There were no additional charges compared to the quote estimate and the work was carried out in the estimated time period which was all encouraging. Also good flexibility in that our first dates needed to be postponed due to high winds. This was done without issue by bladestar.

Amy Carswell

The Greenspan AgencyBladestar showed an excellent technical knowledge and professionality executing works on site. The communication is also a strong point in all stages. They helped us to solve critical problems with a high quality ensuring our collaboration in future projects.

César Urdaniz Mendia

Vector RenewablesBladestar showed themselves with good communication before and during the project. The repair methodology was also transparently and openly communicated on a permanent basis so that all steps could be understood from a technical point of view. This helped us a lot in ensuring quality and we look forward to working with Bladestar again on future projects.