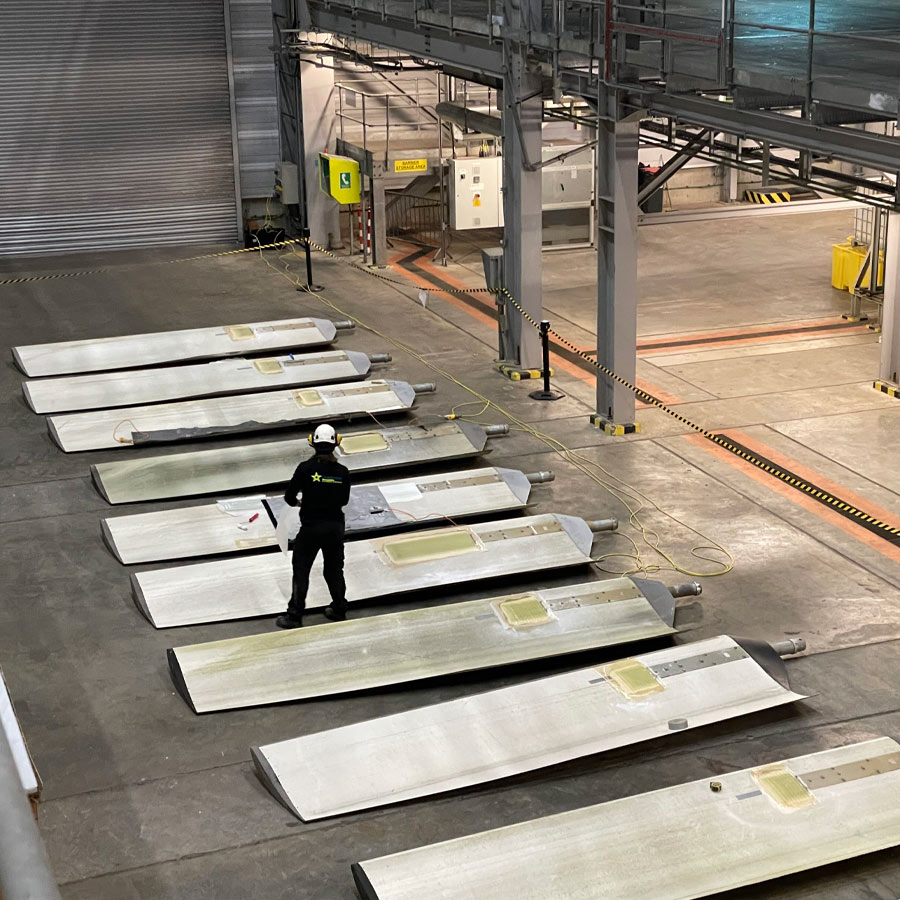

Industrial Composites

Industrial composites are becoming an increasingly popular choice of materials for producing various items. Light in weight they are much stronger than traditional materials such as steel. Albeit very strong they can sometimes be damages within their working environment. Bladestar Renewables Ltd have highly skilled and competent composite technicians to hand to help evaluate and repair any damaged composites. Majority of these repairs can be completed in situ thus mitigating the need for costly removal of parts.

Bladestar Renewables Ltd are experts in repairing composite materials. With a dedicated team whom specialise in multiple composite backgrounds we are sure to provide a solution to your damaged parts/products. A free quote will be issued upon all repair enquiries. We aim to provide the best advice on how to best repair your composite parts. Get in touch with our team here to discuss how Bladestar can save on the massive cost of replacing composite parts!

Long First Rate Warranties

Bladestar Renewables pride themselves on quality service and workmanship. All repairs will come with first rate warranties. We will talk you through the repair strategy and maintain high levels of communication during the project to keep you in the loop!

A full list of our services can be found here.