Key Points

- Previous failed repair by another company

- Repair completed in 40 hours via rope access

- Core replacement and reinforcement required

- Repair report uploaded to Bladestar secure server within 72 hours of completion

Investigation

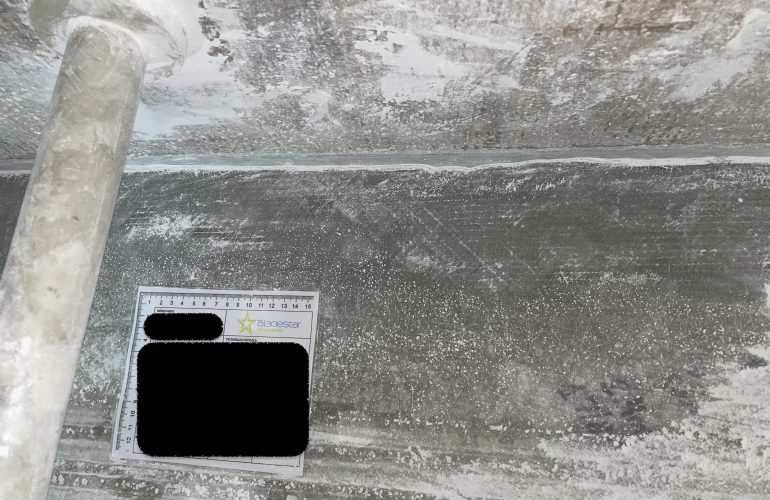

Investigation was started by removing all surrounding paint in the defective area to see if any other defects were visible. This would help us in identifying a root cause analysis. Upon further investigation it was deemed that the old repair had not been sufficiently overlapped. There was also only one layer of fibreglass on the old repair. This was not sufficient and 4 layers should have been used to ensure structural integrity.

- Previous core replacement completed however poor workmanship had left the area too fragile

- Glue joins of the core were out of spec and deemed excessive

- Incorrect fiberglass used under core resulting in debonding from the inner shell

- Wrongly orientated UD found during investigation

Repair

We removed the defective fiberglass to expose the core. A core replacement had been completed however poor workmanship of the replacement had left the area too fragile to withstand the stress load requirements. The glue joins in the core replacement were also out of spec and deemed excessive.

Once the core was removed it was found that the wrong fiberglass had been used under the core resulting in debunking from the inner shell. We removed the defective core and replaced with fresh core following our work instruction. This was then overlapped with the correct amount of fibreglass for the area.

We then structurally profiled the area in preparation for filling and painting. When the repair was finished we had successfully completed a 1.3 metre core replacement with internal shell bonding and a 1.5m x 0.6m reinforcement lamination.

- Repair completed in the time scale agreed - 4 days via rope access

- Significant reduction in material used compared to other companies

- Less downtime of turbine due to efficient repair techniques

- Repair heat treated to ensure superior strength in laminate