Key points

- Substantial crack through external fiberglass, core, and internal fiberglass

- Majority of works completed internally to mitigate external environmental factors

- Bespoke repair plan created

- 175.25 hours to complete via rope access

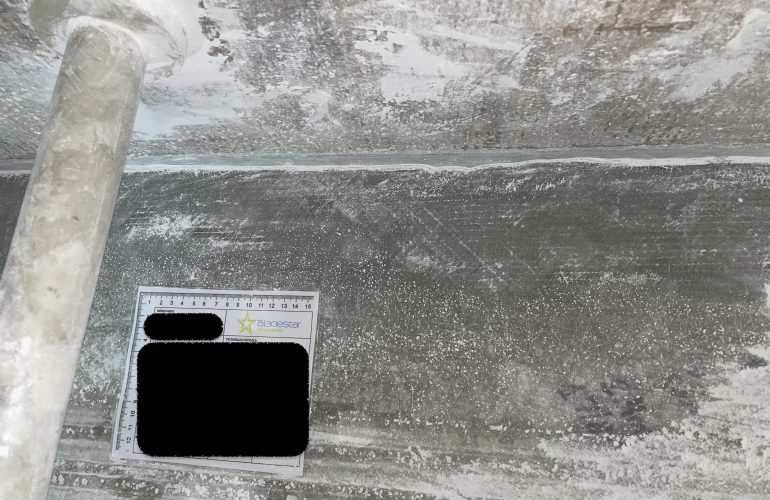

Investigation

The works were started with a thorough investigation of the external and internal crack. It was deemed that there was minimal SPAR damage during the investigation.

- All layers of fiberglass and core were damaged resulting in a guaranteed core replacement

- Core replacement would be completed internally to combat external environmental factors

- External fiberglass would need to be replaced first to ensure area was water tight

External Repair

External fiberglass layers were removed exposing crack in core material. The fiberglass layers were chamfered and replaced in accordance with our work instruction for this repair. Four separate structural laminations were applied to the affected area to rebuild the layers that had been removed. These extra structural laminations were necessary due to the incorrect removal of the spoiler. Cuts were found in the outer fiberglass layers which had been filled in with paint. Due to the nature of these cuts being at varying angles causing structural stress’ across the area these were removed.

Additional fiberglass was layered over the top of the structural laminations in order to spread the load across a greater surface area. This was also reinforcement for the original defect. Upon completion of the laminate, the area was filled using sacrificial laminate and filler to restore the blade profile. The filler was then sanded and area painted.

Internal Repair

Cracks were found to mirror the external defect. As a result of already identifying the core damage we were able to move straight into core replacement reducing the need for further investigation. Minor cracks were identified across the web foot. As a result of this it was decided they would be removed and the over laminate for the main defect would overlap from shell onto webfoot/web.

New core was bonded into place and cacuum consolidated to promote superior adhesion to the outer laminate. Structural lamination was then completed and heat treated to improve strength. The cover laminate was applied in order to spread the load over a greater surface area and to encompass the webfoot and web reinforcements.