Key Points

- 140 metres hub height MST towers

- Design issues causing water ingress to all towers

- Works completed via rope access

Investigation

Before beginning any sealing/taping works it was essential that the sections of the tower were split up and marked appropriately. Due to the size and surface area being worked on it would have been very easy to become disorientated and document the wrong sections being worked on. Through meticulous preparation and planning, Bladestar devised an efficient plan for marking up of the tower which would in turn speed up the repair process.

Repair

In total there were 11 segments. These varied in number of panels as there were more at the bottom and reduced nearer the nacelle. There were x24 horiztonal cover plates on each segment resulting in a total of 264 horizontal cover plates being sealed. There were 98 vertical seams on the tower which resulted in a total of 1078 metres of taping to be applied.

All horizontal cover plates on the tower had been previously sealed during the manufacturing process. This was found to be unsatisfactory and was allowing water to pass behind the plates. It was decided that all previous sealant would be stripped out with the area thoroughly cleaned ensuring a clear surface for bonding of new sealant. Once the area was cleaned, a primer was used to promote superior adhesion for the new sealant. New sealant was then applied providing a much larger seal and better quality than previous. There were also various other sections that included the door and rear vent that were also sealed.

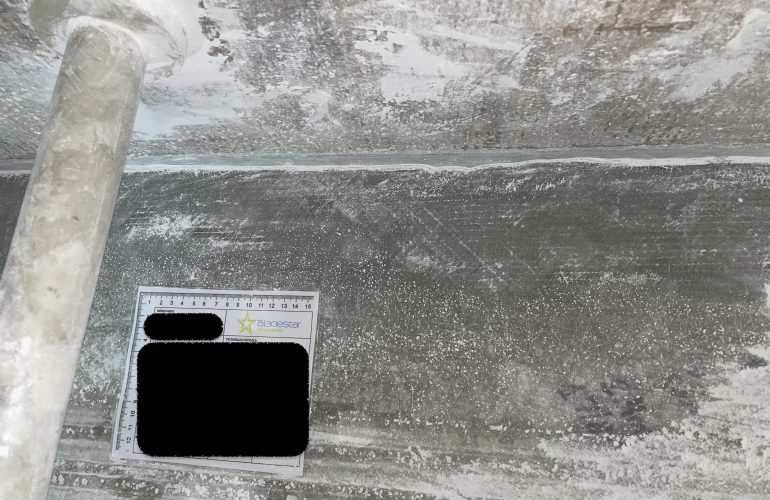

Vertical sections of the tower were previously filled with a special type of foam used during construction. The foam is squeezed into position as the steel plates are forced together. Due to tower oscillations the foam was uneven in places resulting in gaps where water was able to pass through and penetrate the interior.

The solution for this was to remove any protruding foam from the vetical seams. We would then clean the area thoroughly, again to promote adhesion of the specially designed sealant tape.

When complete, the full towers were sealed successfully eradicating previous water ingress issue.

- There were 98 vertical seams on the tower which resulted in a total of 1078 metres of taping to be applied

- Any protruding foam to be removed prior to tape installation

- When complete, the full towers were sealed and taped successfully eradicating previous water ingress issue.