What are Industrial Composites?

Industrial composites are advanced materials made by combining two or more different substances, such as fiberglass, carbon fiber, and resin. These materials offer unique strength-to-weight ratios, making them perfect for high-performance applications in harsh environments. In the wind turbine industry, composite materials are primarily used for blades, but their benefits extend to factories, manufacturing facilities, and other industrial uses requiring strong yet lightweight components.

Why Industrial Composite Materials Are Used in Wind Turbines

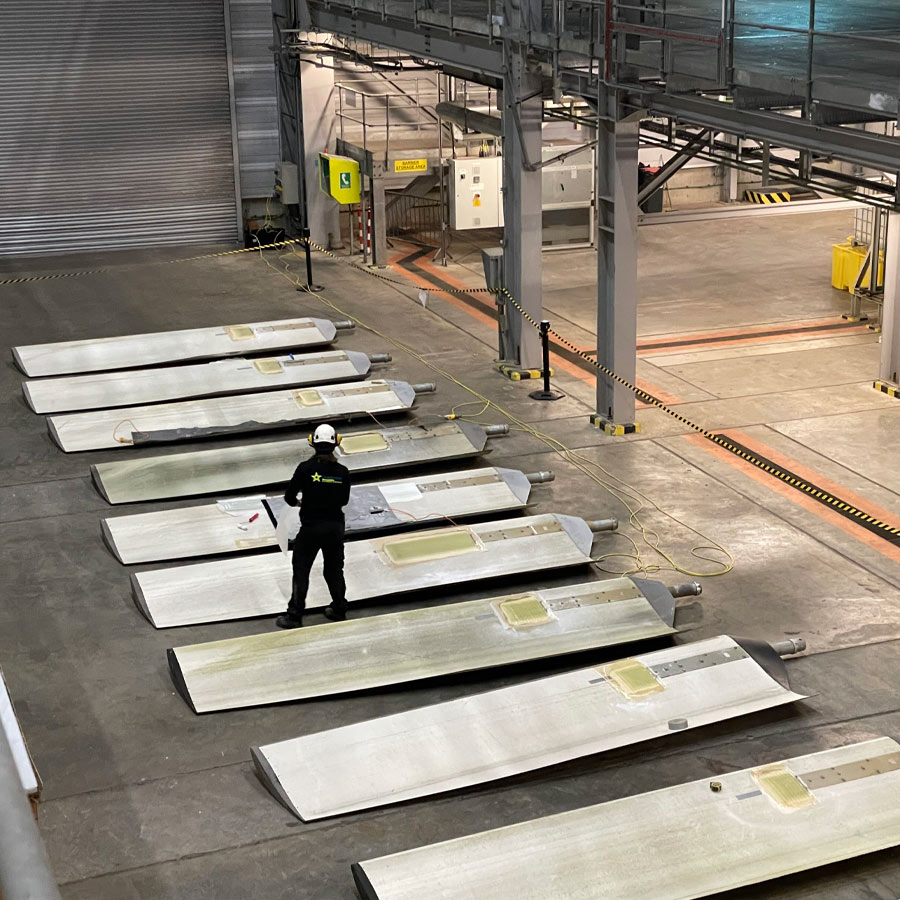

At Bladestar Renewables Ltd, we offer high-quality industrial composite solutions that span across the wind energy, manufacturing, and industrial sectors. With over 20 years of experience, we specialise in the repair, maintenance, and fabrication of industrial composite materials, ensuring optimal performance, durability, and cost-effectiveness for all your critical assets.

Our Expertise in Industrial Composite Work

At Bladestar Renewables, we specialize in industrial composite applications across a range of industries, including:

Wind Turbine Blade Repair: We restore turbine blades with high-performance composite materials, ensuring the longevity and efficiency of wind turbines.

Factory & Industrial Components: Our composite solutions enhance factory machinery, pipes, tanks, and structural elements, offering durability and resistance to corrosion and wear.

Custom Composite Fabrication: We provide bespoke composite solutions tailored to meet the exact specifications and needs of your industry.

Our expert technicians leverage advanced techniques and industry-leading tools to deliver effective solutions that extend the lifespan of your equipment and minimize operational downtime.

Industrial Composite Services We Offer

Wind Turbine Blade Repairs

The blades of wind turbines are highly exposed to environmental stressors and wear. Our industrial composite repair services ensure the blades remain structurally sound and efficient. From repairing cracks and chips to reinforcing blade surfaces, we restore turbine blades to their original condition using high-strength composite materials that ensure maximum durability.

Composite Maintenance for Industrial Machinery

We extend our industrial composite services to factory and industrial machinery. Whether it’s reinforcing piping systems or restoring damaged structural elements, our composite materials are ideal for improving the strength and lifespan of essential components. Our work ensures that your industrial machinery operates efficiently with minimal interruptions.

Custom Composite Solutions

We understand that each industry has unique requirements, and our team is equipped to provide custom industrial composite solutions. Whether you need specialized repairs or custom-designed components, Bladestar offers tailored services that meet your exact specifications.

Industries We Serve

Bladestar Renewables provides industrial composite solutions across a wide range of industries, including:

Wind Energy: Blade repair and maintenance for turbines of all major brands.

Manufacturing: Composite reinforcement and repairs for factory machinery and structural components.

Oil & Gas: Durability-enhancing solutions for pipelines, tanks, and offshore structures.

Marine: Custom composite fabrication for boats, ships, and offshore platforms.

Construction: Reinforcement of structural elements to improve strength and longevity.

Our broad industry experience allows us to offer tailored solutions that meet the specific needs of each sector.

Why Choose Bladestar Renewables?

Proven Track Record Across Industries

With over two decades of experience, Bladestar Renewables has earned a strong reputation for delivering exceptional industrial composite solutions to a range of industries. We’ve successfully completed projects in wind energy, manufacturing, and beyond, helping clients achieve operational excellence through our durable and high-performance composite materials.

Fast and Cost-Effective Solutions

We understand that time is money, and minimising downtime is crucial to your operations. Our efficient industrial composite repair and maintenance services are designed to reduce downtime and deliver cost-effective solutions. We work around your schedule to ensure your projects are completed on time and within budget.

Expert Technicians and Advanced Technology

Bladestar’s team is composed of highly skilled technicians who specialize in industrial composites. Our use of cutting-edge technology—including drones, ultrasonic testing, and thermography—ensures that all repairs and inspections are carried out to the highest standards of quality and precision.

Safety and Compliance

Bladestar Renewables places a strong emphasis on safety and industry standards. Our team follows strict safety protocols and ensures compliance with all relevant regulations. You can trust us to handle your industrial composite projects with professionalism and care.

Get In Touch With Bladestar Renewables

Looking for reliable industrial composite solutions? Whether you need repairs, maintenance, or custom solutions for your wind turbines, factory components, or other industrial needs, Bladestar Renewables has the expertise you can rely on. Contact us today to learn how we can support your operations with our high-performance industrial composite services.

I have worked with Chris and Bladestar extensively over the last two years on various blade repairs on the sites I oversee, and I can honestly say the Bladestar team are professional in all aspects. Their approach to each repair is unique and innovative and any hurdle encountered is met head-on with skill, knowledge and professionalism.

They have exceptional communication and they have consistently demonstrated their capacity to convey complex ideas with clarity and precision, both in writing and speech. Chris and his team’s dedication to accuracy is evident in all aspects of the repair work they have conducted for our sites, They have a keen eye for detail that ensures all information is conveyed correctly and without misunderstanding.

In addition to their communication skills, Chris and his team have proven time and again to be a reliable and committed team player and their positive attitude and ability to adapt to changing circumstances make them a valuable asset.

Mark Haggerston

Bladestar have been a great support to us during blade works with their detailed knowledge, experience and expertise in all areas of rope access. Their proactive approach to their projects has ensured that our 2024 blade repair campaign has went flawlessly. Their cost benefit analysis during an unforeseen critical repair allowed one of our assets to be repaired promptly and to a high quality. Thank you Bladestar for a superior service and look forward to working with you in the future.

Nils Ferguson

“We recently worked with BladeStar Renewables for extensive blade repairs on one of our LM 45.3P blades with the notorious chordways cracks, and we couldn’t be more satisfied with their performance. The team demonstrated exceptional expertise and professionalism throughout the entire process.

From the initial inspection to the completion of the repairs, their attention to detail and commitment to safety were evident. The quality of their work has ensured the optimal performance and longevity of our turbine blades.

We were particularly impressed by their efficiency in minimizing downtime and their clear communication at every stage. It’s rare to find a service provider with such a high level of technical skill combined with outstanding customer service.

We highly recommend BladeStar Renewables to anyone in need of reliable and high-quality wind turbine blade repairs.”

Michael Blohm

EDF has a wide and varied fleet of wind turbines which generates One Gigawatt of renewable energy. This sizeable fleet requires constant maintenance from specialist personnel and contractors in order to maintain the highest possible efficiency, one of those contractors is Bladestar Blade Repair.

Mark Haggerston

After suffering from Failures in Our hybrid cooling tower blades I was contacted by Blade Star who were confident they could provide a solution to enable us to

Repair our cracked blades and reuse them rather than disposing of them,

The repair procedure was fast, efficient, economical and it was well received as where the employees from blade Star

The repaired blades have been refitted to the cooling towers and have proved there worth and have been on the units for over a year with no failures,

Luke

In my role as supervisor, I oversee a major wind farm project in Germany. Due to design adjustments, some towers had to be sealed from the outside. We ordered a subcontractor to the site to carry out the work. The team leader was Chris Gillies from Bladestar Renewables Ltd. He had his team were very careful during the work process and extremely fast and cooperative. Punctuality was also a top priority. In addition, Bladestar were able to contribute very good suggestions for improving the sealing processes thanks to their many years of experience! The quality of the work carried out was very high. All in all, the team were a pleasure to work with. We would hire Bladestar again at any time!