When you’ve spent years on the ropes, working turbine after turbine in all weather, you learn what works — and what just sounds good on paper.

Too often, we hear armchair experts talk about blade repair as if it’s a lab-controlled process. Factory methods. Engineering theory. Textbook perfection. In reality? Wind turbine blade repair is dynamic, high-pressure, ever-changing world of turning theory into practical application, all the while keeping safe from chemical exposure at 30-90m in the air — it’s done in the field and we do it well.

Let’s break down why that matters.

1. Repairs Happen Where the Damage Is

Turbines don’t come to you. You go to them.

We repair blades hundreds of feet in the air, heat and wind -That means rope access work, mobile kits, and decisions made with boots on the ground — or hanging in a harness.

Factory conditions are ideal. But they’re not real.

Real-world repairs happen with time pressure, limited access, and strict safety rules. You don’t get five different prep stations and a temperature-controlled resin booth. You get your gear, your experience, and your process — refined by doing it again and again.

2. Field Techs Solve Problems You Can’t See From a Desk

Blade damage isn’t just what’s visible. It’s about knowing where to look, what to tap for sound, and how to read the surface.

An internal delamination doesn’t show up in a spreadsheet. A hairline crack doesn’t flag itself in a maintenance schedule. You need hands on the composite, and a brain trained by hundreds of previous jobs.

Our technicians don’t guess. They assess.

That comes from in-house training and field experience — not just qualifications. There’s no shortcut to learning what certain damage sounds like when tapped, how fiberglass behaves in different conditions, and why resin ratios matter.

3. Yes, We Know the Science — But We Work With What We’ve Got

We’ve read the manuals. We know the chemistry.

But we also know you can’t wait three weeks for ideal conditions while your turbine’s offline.

Rope access blade repair means balancing technical standards with practical reality. We use the right materials. We prep correctly. And if conditions aren’t right? We wait.

But when the window opens, we’re ready — because we planned for it.

That’s what separates a good team from a risky one. Not just knowing the theory, but being able to apply it at 90 metres up, before the weather closes in again.

4. Factory Repair Assumes Time. Field Repair Respects It.

Downtime costs money. A lot of it.

Every hour a turbine’s off, you’re losing revenue — and maybe delaying grid contribution. Factory-level repair thinking can lead to over-engineered solutions and unnecessary hold-ups.

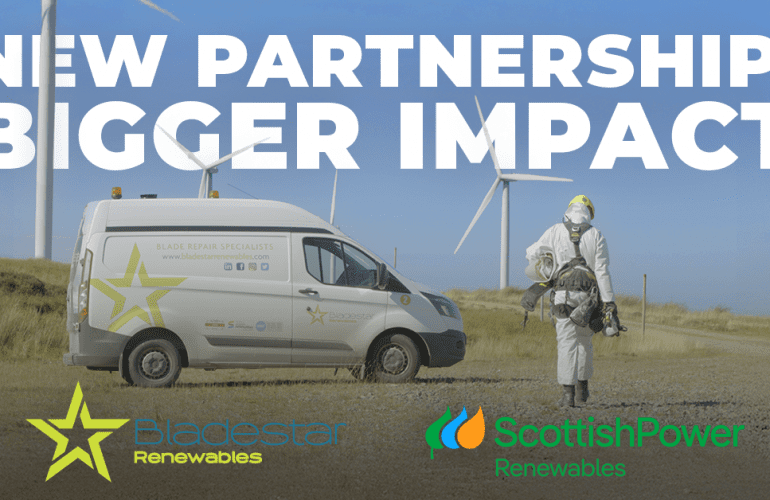

At Bladestar, we focus on what’s needed to make the blade safe, functional, and compliant — nothing more, nothing less.

That’s not cutting corners. That’s cutting the fluff.

We assess damage properly, communicate clearly, and get the job done without wasting time, money, or your patience.

5. You Can’t Replicate Rope Access in a Workshop

No MEWP. No platform. Just ropes, techs, and skill.

We don’t need external support to complete isolations.

Our in-house LATs handle that. That frees up client resources and means we can get to work faster and for longer — no waiting on third parties.

This matters, because access delays are one of the biggest hidden costs in turbine maintenance. When your team can do everything from isolations to signoff — all safely and in-house — you win back control.

6. Field Repair Means Documentation You Can Trust

Just because we’re hanging from a rope doesn’t mean we cut back on reporting.

Every job comes with photo documentation, clear descriptions, and transparent defect logs.

Clients don’t want guesswork or generic reporting. They want to know what we found, what we did, and how it was resolved. That’s what we deliver — every time.

Customers also benefit from access to our Customer Portal (FREE OF CHARGE), where they can view live pictures as they are taken in real time to keep track of repair status and quality checks. Customers also have the ability track expenditure from the portal and also book quotes/jobs in the portal with all their assets on display.

🛠️ 7. Bladestar Prepares Like a Factory, Performs Like a Field Team

Here’s the truth: we respect the science.

But we don’t pretend turbines are sitting in clean rooms.

Bladestar combines rigorous prep, proven repair methods, and smart planning — so that by the time we’re on site, there’s nothing we haven’t thought through.

- Custom kits packed for each job

- Trained rope techs with composite repair expertise

- Internal isolations and access handled without delay

- Full compliance and documentation

That’s what proper wind turbine blade repair looks like — outside the factory and in the real world.

Want to See It in Action?

We’ve worked across the UK and beyond, repairing composite blade damage with zero compromise on safety or quality.

Learn more about our approach to on-site blade repairs.