Precision, Performance, and Reliability in Every Rotation

At the heart of every wind turbine lies one crucial component — the turbine blade. Designed for strength, efficiency, and aerodynamic perfection, each blade plays a vital role in capturing the natural power of the wind and turning it into sustainable energy.

For operators and asset owners, understanding how turbine blades work — and how to keep them performing — is key to maintaining long-term reliability and maximum output. At Bladestar Renewables, we specialise in turbine blade inspection, repair, and maintenance.

Our expert technicians ensure every blade continues to operate safely and efficiently, helping our clients extend asset life and optimise energy production.

What Is a Wind Turbine Blade and What Is Its Main Purpose?

A turbine blade is the driving force behind every wind turbine — the component that captures the kinetic energy of the wind and converts it into mechanical power. As the blades rotate, they drive the turbine’s rotor, generating the movement that is transformed into clean, renewable electricity. In short, the turbine blade is what turns natural wind into reliable energy.

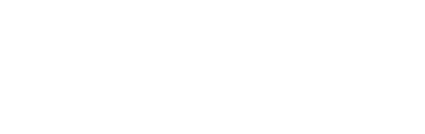

How Many Blades Does a Typical Wind Turbine Have, and Why?

Most modern turbines have three blades, carefully engineered to achieve the ideal balance of aerodynamic performance and mechanical stability. Three blades minimise vibration, improve efficiency, and maintain a smooth, steady rotation — even under high wind loads.

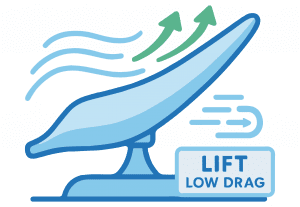

How Does a Wind Turbine Blade Actually Generate Electricity?

Turbine blades work using aerodynamic lift, much like an aircraft wing. As wind passes over their curved surfaces, it creates lift, causing the rotor to spin. This rotation turns a shaft connected to a generator, converting kinetic energy into electrical energy — feeding clean, renewable power into the national grid.

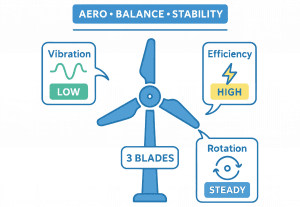

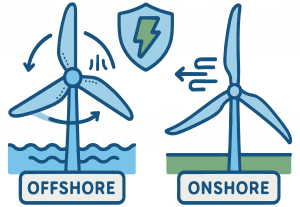

What Size Are Wind Turbine Blades, and Does This Vary Between Models?

Yes — turbine blade size depends on the model, capacity, and environment of the turbine. Onshore blades usually measure between 40 and 70 metres, while offshore blades can reach 100 metres or more to capture stronger, steadier coastal winds. The larger the blade, the more energy it can produce.

How Much Does a Typical Wind Turbine Blade Weigh?

A single turbine blade can weigh anywhere from 10 to 35 tonnes, depending on its size and material composition. Despite their enormous scale, blades are crafted from lightweight yet durable composite materials like fibreglass and carbon fibre — built to endure years of continuous operation in extreme weather conditions.

Why Are Turbine Blades Shaped the Way They Are?

The curved, aerodynamic shape of a turbine blade allows wind to flow smoothly over its surface, generating lift and rotation. Each blade is twisted and tapered to maximise energy capture from root to tip, reducing drag and improving efficiency across a range of wind speeds.

How Fast Do the Blades Spin During Operation?

While they appear to turn slowly from the ground, turbine blades rotate at 10–20 revolutions per minute (RPM). The tips can travel at speeds exceeding 150 miles per hour, efficiently converting wind energy into motion without overloading the system or causing structural stress.

Are All Turbine Blades the Same, or Are There Different Designs for Different Conditions?

No two turbine blades are exactly alike. Designs are adapted for specific wind conditions and environments. Offshore blades are typically longer and more robust to harness consistent sea winds, while onshore designs are optimised for fluctuating airflow over land. Specialised coatings and materials protect against lightning, corrosion, and leading-edge erosion, ensuring long-term durability and performance.

Trust the Experts in Turbine Blade Care

Your turbine blades are the foundation of your renewable energy performance — and keeping them in prime condition is essential. At Bladestar Renewables, we provide expert wind turbine blade repair, inspection, and maintenance across the UK. Our certified technicians use cutting-edge technology and proven repair techniques to ensure your blades perform safely, efficiently, and for longer.

📞 Get in touch today to schedule an inspection or learn how we can help extend the life of your wind assets.